Public Fidelity

Member

Thread Starter

- Joined

- May 6, 2024

- Messages

- 6

Hey everyone!

Just wanted to share a quick project I recently worked on: an automated loudspeaker measurement turntable controlled directly from REW (Room EQ Wizard).

I built this turntable to streamline my loudspeaker measurements and make the process more efficient. With REW's API-control (Beta release), I can precisely rotate the turntable to capture data at different angles, allowing for spinorama measurements without the need for manual adjustments. The setup has been a game-changer for me, saving time and ensuring accuracy in my measurements.

Here are some pictures with a small explainer:

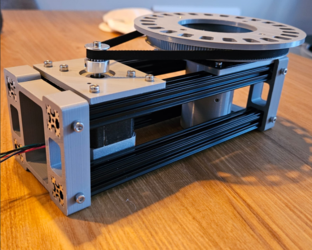

The table (made from the Audiomatica Medusa project files)

Table in action

I wrote a custom controller that uses the REW-API (in beta release)

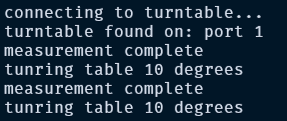

This is log from controller:

It uses the measurement 'Increment' number as rotational distance input for the turntable.

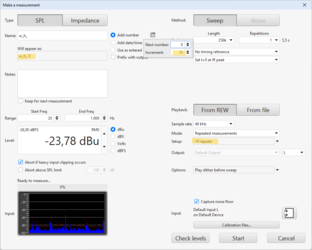

The 'Repeated measurement' feature in REW allows for automated repeat.

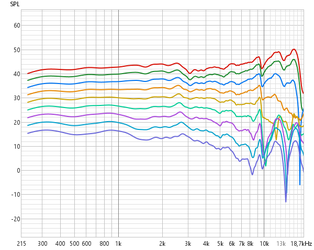

Example of 0 - 80 degrees measurement sequence (gated)

Happy to answer any questions or share more details if anyone's interested.

Just wanted to share a quick project I recently worked on: an automated loudspeaker measurement turntable controlled directly from REW (Room EQ Wizard).

I built this turntable to streamline my loudspeaker measurements and make the process more efficient. With REW's API-control (Beta release), I can precisely rotate the turntable to capture data at different angles, allowing for spinorama measurements without the need for manual adjustments. The setup has been a game-changer for me, saving time and ensuring accuracy in my measurements.

Here are some pictures with a small explainer:

The table (made from the Audiomatica Medusa project files)

Table in action

I wrote a custom controller that uses the REW-API (in beta release)

This is log from controller:

It uses the measurement 'Increment' number as rotational distance input for the turntable.

The 'Repeated measurement' feature in REW allows for automated repeat.

Example of 0 - 80 degrees measurement sequence (gated)

Happy to answer any questions or share more details if anyone's interested.

Last edited: