Jororaitchev

Member

More

- Preamp, Processor or Receiver

- Marantz 6009

- Universal / Blu-ray / CD Player

- OPPO105D

- Front Speakers

- DIY_ "J&N"

- Center Channel Speaker

- DIY_ "J&N"

- Surround Back Speakers

- DIY_ "J&N"

Perhaps a misunderstanding may is there have occurred,

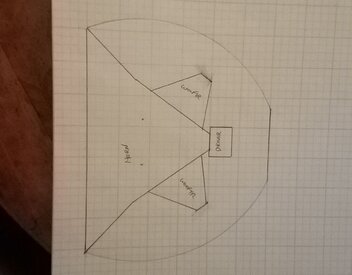

These positions are from one of my projects that had to be fundamentally altered at the outset.

It does not matter, we forget about this idea and we are going forward. Rear- speakers project :

The loudspeakers are "SEAS"- Excel T25CF002-1", W18EX001- 6,5"

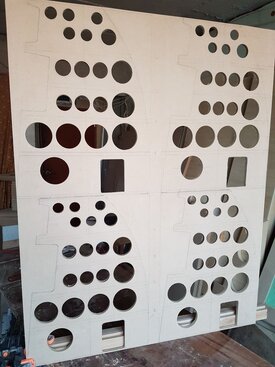

Everything is handmade, no "CNC" machine is used.

These positions are from one of my projects that had to be fundamentally altered at the outset.

It does not matter, we forget about this idea and we are going forward. Rear- speakers project :

The loudspeakers are "SEAS"- Excel T25CF002-1", W18EX001- 6,5"

Everything is handmade, no "CNC" machine is used.